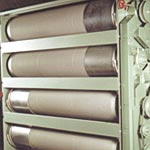

Crippen Northland Superior’s NS Series is the industry’s leading line of indent cylinder length separators, and offers a full range of sizes, capacitiesand configurations to meet every length separation application. With a modular design and two cylinder sizes – the NS-B and NS-S Series – numerous variations are available, with capacities ranging from 160 bu/hr up to 6000 bu/hr.

Crippen Northland Superior’s NS Series is the industry’s leading line of indent cylinder length separators, and offers a full range of sizes, capacitiesand configurations to meet every length separation application. With a modular design and two cylinder sizes – the NS-B and NS-S Series – numerous variations are available, with capacities ranging from 160 bu/hr up to 6000 bu/hr.

Rigid enclosed frame construction and poly belt chain drives provide smooth, vibration-free performance with low energy consumption. Manufactured to the highest standards, all Crippen Northland Superior Indent Separators require only routine maintenance to ensure years of trouble-free operation. All parts subject to wear are readily accessible and easy to replace.

The rotating 23″ or 17″ diameter indent cylinder, case-hardened for optimum life, is the key component of the NS series separators. Available in a wide range of indent pocket sizes, NS cylinders can remove large or small material as desired to meet every separation requirement.

Simple operating adjustments allow for a wide variation of products to be separated by the NS Indent Cylinder Separators. The separating edge (A) can be raised or lowered, allowing the receiving trough (B) to catch desired liftings of shorter grains as they drop free from the cylinder indents (C). Turning the hand wheel (D) adjusts the position of the separating edge, with the pointer (E) showing the position on the indicator dial (F). The inspection door (G) allows observation of the cylinder separation process.

Simple operating adjustments allow for a wide variation of products to be separated by the NS Indent Cylinder Separators. The separating edge (A) can be raised or lowered, allowing the receiving trough (B) to catch desired liftings of shorter grains as they drop free from the cylinder indents (C). Turning the hand wheel (D) adjusts the position of the separating edge, with the pointer (E) showing the position on the indicator dial (F). The inspection door (G) allows observation of the cylinder separation process.

The liftings are transported out of the receiving trough by a screw conveyor. Grain line blades (H) connected to the bottom of the trough ensure a steady grain flow along the length of the indent cylinder. The flow of the unlifted longer material (tailings) exiting the cylinder is controlled by the adjustable retarder blade (I).

Standard Features

- Two basic cylinder diameters: 23″ (NS-B) or 17″ (NS-S)

- Long-wearing case hardened and reversible cylinder shells

- Indent pockets available in wide range of sizes

- Receiving trough adjustment for precise separation; dump position for complete clean-out

- Retarder adjustment to maintain desired grain level

- All controls accessible and easy to operate

- Dual-drive configuration for five-row-high models

- Poly drive belts for smooth performance and long life; no lubrication; maintenance-free

- All wear components are readily accessible and easy to change

Options

- Custom spouting configurations

- Stainless steel, ceramic or urethane spouting liners for longer life

- Cross screw conveyors from discharge spouts

- Actuator-controlled trough adjustment

- Chrome-plated cylinder shells

- Cylinder wear bands

Modular Design

Multi-cylinder arrangements from one to 30, up to five high and six wide, provide complete flexibility to meet any application.

Choice of Various Flow Options to Suit All Separation Requirements

Parallel flow is characterized by the same product flow directions for each cylinder row. From a main spout, the product is equally distributed to cylinder rows from one side of the machine.

Parallel flow is characterized by the same product flow directions for each cylinder row. From a main spout, the product is equally distributed to cylinder rows from one side of the machine.

Series flow allows for multi-separation from one stream and is characterized by the counter-flow directions of the separated product for each cylinder row. The product enters the first cylinder row and flows back through the row below.

Series flow allows for multi-separation from one stream and is characterized by the counter-flow directions of the separated product for each cylinder row. The product enters the first cylinder row and flows back through the row below.

Parallel and Series Flows May Be Combined in One Machine