The new NS-SC Seed Cleaner is designed and manufactured by Crippen Northland Superior for accurate separation of any commodity on the basis of length difference.

The new NS-SC Seed Cleaner is designed and manufactured by Crippen Northland Superior for accurate separation of any commodity on the basis of length difference.

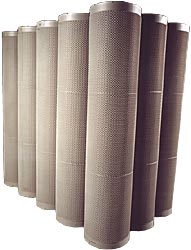

The modular design allows the NS-SC to be used individually or arranged as a multiple-cylinder machine. A variety of interconnecting spouting arrangements provides for a wide range of flows.

The NS-SC separator is a simple, single-cylinder machine utilizing a main drive, conveyor shaft and cylinder as the only moving parts. A 17″ diameter cylinder, hardened for optimum life, is the primary component of the NS-SC. The size of the indent pockets on the inside surface of the cylinder determines the length of the lifted material. Any material the same size as or smaller than the indent pockets is lifted and dropped into the receiving trough. The transportation of the material from the trough to an outside spout is performed by a screw conveyor. The remaining larger material is taken to the discharge spout by grain line blades connected to the outside bottom of the trough.

A 1/2 H.P., 1800 RPM motor mounted inside the body of the machine allows variable speed through a V-belt drive and reducer.

Great Flexibility

Indent cylinders are available in many sizes to suit a wide variety of separation needs. Variation in separating performance can be achieved by several easy adjustments.

Indent cylinders are available in many sizes to suit a wide variety of separation needs. Variation in separating performance can be achieved by several easy adjustments.

- Cylinder speeds variable from 35 to 60 RPM

- Wide range of trough angles

- Retarder control for grain depth

All controls are within easy reach of the operator.

Easy Cylinder Change and Cleaning

The NS-SC separator is easily and quickly cleaned.

machine can be mounted on a slight incline to allow faster cleaning

machine can be mounted on a slight incline to allow faster cleaning- removable doors give easy access to the cylinder compartment for easy cleaning and maintenance

- optional split cylinder construction allows fast replacement of cylinder

- Crippen Northland Superior’s advanced surface hardening process ensures the cylinders are both long-lasting and round.

- The universal design of Crippen Northland Superior’s cylinders enable them to be used on other manufacturers’ 17″ cylinder machines.

Easy Operation and Maintenance

Simple construction and smooth, vibration-free operation are factors making the NS-SC separator very efficient in all aspects of operation and maintenance. The NS-SC separator is solidly constructed, and only routine maintenance is required to ensure years of trouble-free operation.

Standard Features

- Adjustable retarders

- Trough locking mechanism

- Motor mounted inside the frame of the machine

- Trough adjustment for complete clean-out

- Dust control connection at the discharge end for dust-free operation

- Variable-speed operation

Modular Design

Modular Design

Any number of complete modules can be put together in a series flow (to reclean either liftings or tailings) or parallel flow for maximum capacity.

Options

- Location of the cylinder speed handwheel at the discharge end

- Feeder providing uniform feeding

- Spouting kits for stacking machines in parallel or series flow

- Lined infeed casting

- Split cylinder shells

Internal Drive

Internal Drive