Principles of Optical Sorting

Optical sorters utilize reflected light to analyze products that have been singulated and presented to the viewing area.

Optical sorters utilize reflected light to analyze products that have been singulated and presented to the viewing area.

This singulation can be achieved utilizing low-friction inclined chutes or conveyor belts. Specially designed optical filters narrow the reflected light into specific wavelengths that accentuate the difference between the acceptable product and the product to be rejected. Specialized CCD, IR, UV or RGB (full-color red/green/blue) cameras receive the reflected light from the product and send this information to be amplified and classified. For a monochromatic sorter, there is only one filter in front of the camera, producing a basic light/dark separation. For a bichromatic sorter, two filters (Visible/Visible, Visible/IR or IR/IR) are used to combine multiple wavelengths and provide for separation of less obvious color differences. Color sorters utilizing RGB technology use a full-color camera instead of optical filters and can be programmed to sort products that may be difficult with other technologies. Utilizing the user interface, the operator programs in the parameters for acceptable product and product to be rejected. Once the machine determines that an object falls outside the acceptable parameters, a high-speed ejector is activated at the precise time the product passes the ejector nozzle. The good project continues in a straight line and the rejected product is removed from the good stream.

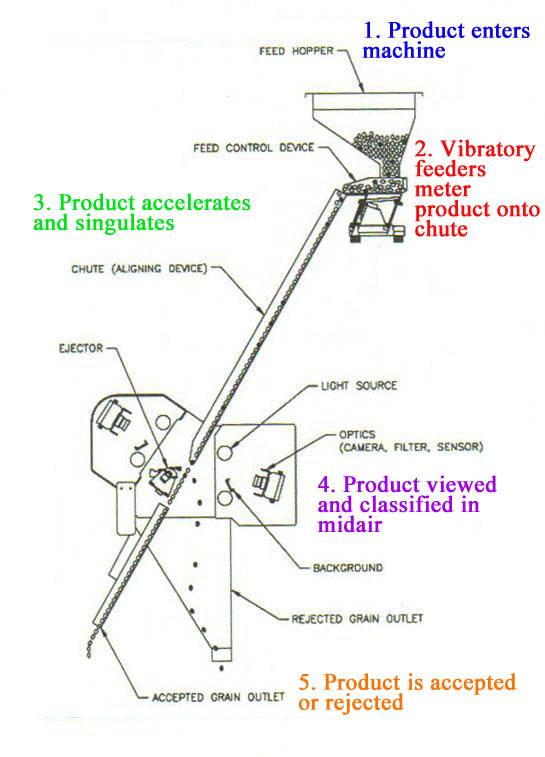

- Product enters machine

- Vibratory feeders meter product onto chute

- Product accelerates and singulates

- Product is viewed and classified in midair

- Product is accepted or rejected

How Color Sorters Work